Lead Contact

Samuel Hellman, PhD

Medical Physics

Memorial Sloan Kettering Cancer Center

For more information contact

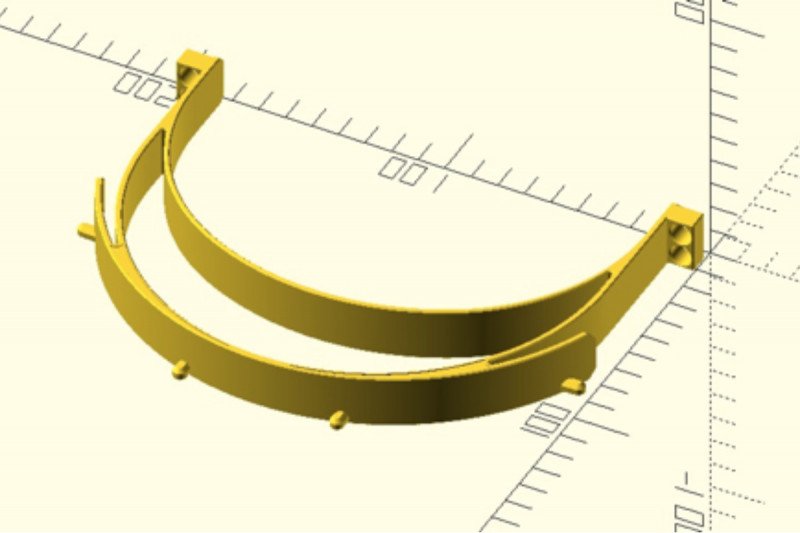

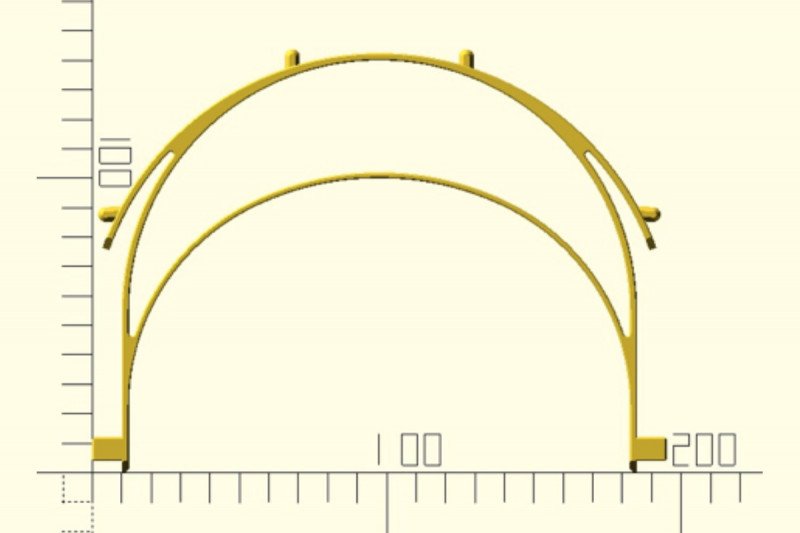

A team of physicians and engineers at MSK has redesigned the framework to support the face shield — an essential part of the personal protective equipment ensemble currently in high demand — allowing for quicker 3D printing and improving wearer comfort.

The new design is a modified version of the RC2 design by Prusa (2) but uses a different strap and thicker material than the specifications from Prusa enabling us to eliminate the lower support piece in their design.

Clinical Need

SARS-CoV-2, the virus that causes COVID-19, is spread through respiratory droplets such as when a patient coughs, sneezes or even talks (1). Healthcare workers who work closely face-to-face with COVID-19 patients are especially at higher risk for infection and require face protection to prevent inhalation of viral droplets or aerosols. Face shields cover a large area of the face, often shielding part of the neck as well. They not only serve as a form of PPE but can prevent the contamination of and prolong the use of other PPE components such as N95 masks.

Innovation

The headband of our face shield consists of a polyurethane cord folded over on itself through loops in the structure and is fully adjustable for head circumferences. The design is more comfortable for most users and avoids edge effects inherent in designs that rely on discrete headband sizes (which can be too loose or too tight).

How To Make the Device

Our face shield has the same dimensions as the RC2 design by Prusa. The modifications were made for easier printing, easier cleaning, and better comfort.

The cord is made of polyurethane and is about 0.25 inch in thickness. The shield component is polycarbonate that is 0.02 to 0.03 inch thick. Due to supply availability, we used various materials for the headband. PLActive AN1 — a PLA with nano-copper additives providing antimicrobial properties - theoretically may be the superior choice for headband material (3).

Using the Device

After putting on the face shield, the black cord can be pulled to tighten. For ease of production and to allow the headband to conform to the wearer’s head, a gap exists between the top of the face shield and the headband. We suggest wearing an impermeable bouffant cap that stretches across this gap to prevent droplets and aerosols from entering this area. If needed, gauze or other soft disposable padding can be placed at the front of the headband for increased comfort.

Cleaning

The face shield can be wiped down with any disinfecting wipes such as Sani-Cloth wipes. Additionally, the headband should be immersed in 70% ethanol solution.

References

- Asadi et al. Aerosol emission and superemission during human speech increase with voice loudness. Sci Rep. 2019. 9: 2348.

- https://www.prusa3d.com/covid19/

- Doremalen et al. Aerosol and surface stability of SARS-CoV-2 as compared with SARS-CoV-1. N Engl J Med. 2020.

Contributors

Sam Hellman, PhD – MSK Medical Physics

Takeshi Irie, MD, PhD – MSK Anesthesiology and Critical Care Medicine

Howard Teng, MD – MSK Anesthesiology and Critical Care Medicine

Larisa Storozhenko, MD – MSK Anesthesiology and Critical Care Medicine

Minsi Zhang, MD, PHD – MSK Resident

The MSK COVID Safety Innovations Team